Treatment

We are able to offer Tanalised E Treatment.

Suitable for Use Classes 1, 2, 3 & 4

TANALISED E pressure treated timber has been impregnated with TANALITH E, a waterborne product based on copper triazole technology. Copper is derived from recycled sources and triazoles are organic biodegradable biocides, commonly used to protect many of the food crops we eat. TANALISED E pressure treated timber is usually specified for both in and out of ground contact applications where there is a medium to high risk of decay or insect attack.

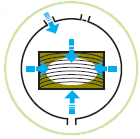

The Treatment Process...

|

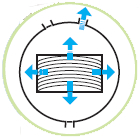

1.Timber is loaded into treatment vessel. Initial vacuum is applied - timber cells evacuated of air. Vacuum held. |

|

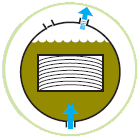

2.Cylinder is flooded under vacuum with Tanalith® E wood preservative. |

|

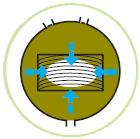

3. Hydraulic pressure is applied, forcing the preservative deep into the structure of the timber. |

|

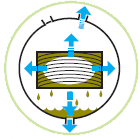

4. Final vacuum extracts excess preservative solution, which is pumped back to storage. |

|

5. Low pressure inside the timber draws in surface solution when vented to atmosphere. Treated timber is left to dry. |

| • An established and proven alternative to traditional chromated/copper/arsenate (CCA) treated timber. |

| • Effective long-term protection against fungal and insect attack. |

| • Proven performance, widely used and accepted worldwide. |

| • Appealing natural green colour with excellent colour durability, blending perfectly with nature. |

| • Impregnated using vacuum pressure technology. |

| • Conforms to new European Standards and individual countries' national requirements. |

| • Ideal for general construction, fencing, garden and leisure timber applications. |

TANALISED® E pressure treated timber can have a service life of 15 - 60 years depending on its end use.

The colour of TANALISED® E pressure treated timber slowly weathers from an initial green hue to a warm, honey brown and in the longer term to a natural silver grey. If required the colour can be refreshed with a brush-on colour product such as RESTOL® (Tanalith® Green).

Any timber surface exposed by cross cutting, drilling, notching or boring must be brushed with ENSELE® end-grain preservative to maintain the integrity of the treatment.

As TANALISED® E pressure treated timber is a high performance product, it is appropriate to use metal fixings and fastenings that give a comparable service life. Under normal conditions the use of hot dipped galvanised nails, screws and fixings is recommended.